|

|

THE

3 GEARS TRANSMISSION |

We can say that a Guzzi recognizes from its "scratched" and from its

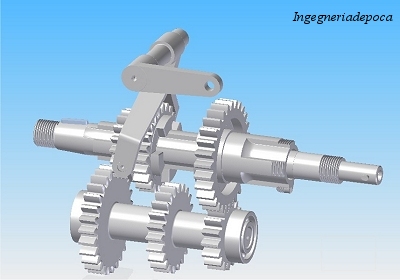

rhythmics sonority of exhaust. The Motorbike Guzzi begins with the "Normale" gear with three speeds "train baladeur", with gears moving on the primary and secondary shaft (made by 3 fixed gears). An handle lever is the mechanism command; it acts on a fork, the consequent pair of gears' axial movement through frontal grafts allows the speed changing. The first gear grafts throwing upward the lever and the others downward passing through the neutral ratio; to insert the first gear or to downward the gears asks delicacy to avoid noisiness. From this simple scheme is evident that main trouble of this kind of gear system is the noisiness or "scratched". All the following models with 3 speeds don't have big changes in the time. The speed-box is in block with the crank.case since that time, contrarily to all the others motorcycles especially in the years '20. This is surely a Guzzi innovation. The "Normale" the Sport (13) and the motor n� 5400-5600 had the gear system lubrication separated by the crank, (years 1926-1927). Often, the grease was the most used lubricate. It is interesting to notice that there was no exhaust hole for the oil change. In the figure is visible a layout of a 3-speed change in use from "Normale" to the "Sport 15" up to 1939.

"Normale" gears system layout. The secondary shaft

is with 3 gears and 2 gears are in the primary shaft. The moving

gears are "train baladeur", the third is the direct

speed

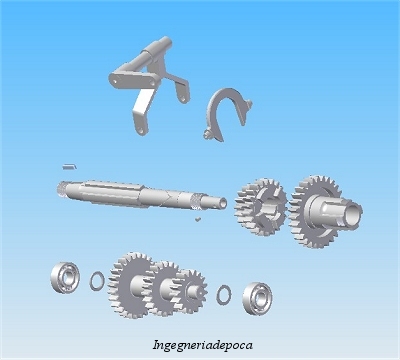

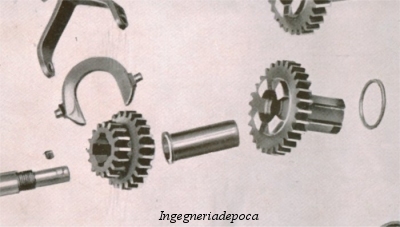

The first versions had then the direct driving at direct contact with the primary shaft, then the bearing was inserted but only in the "Sport" model in 1927. The first racing bike the C2V (with valves in head and with frame already modified in comparison to the "Normale") had different ratios: 25 teeth for the direct drive and 19 teeth on the triple gear, against the 27/17 of the "Normale". This allowed the C2V to reach a greater speed. But substantially, up to 1939 (the last "Sports 15") the gear system version remains also always the same (according to the ratios). The military motorbikes as the GT 17 have a different ratios (in the case, shorter).

"Normale" gears system 3D layout: you can see the fork (operated handly by a lever); the linearity of the details is advantage of a rational and strong planning.

Detail of the direct drive with bearing adopted by the "Sport" models,

1927.

|

|

3 GEARS PRIMARY TRANSMISSION |

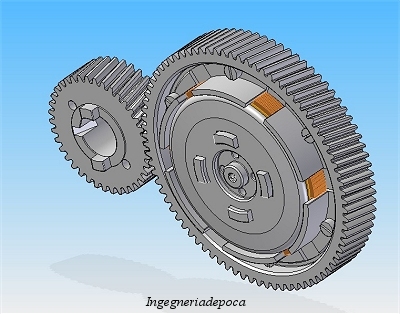

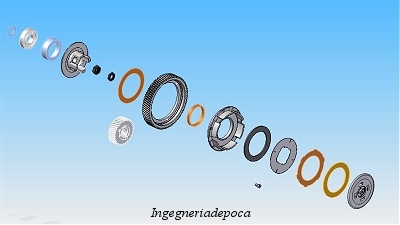

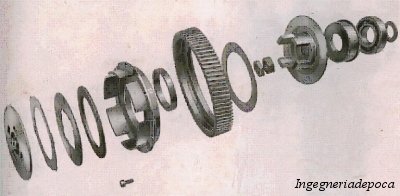

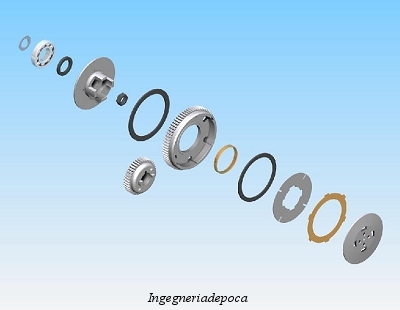

Constituted by a pair of teeth helical gears, ratio 80/38 and with a friction body and steel disks brass and lining. The lubrication is by oil vapors by banging of speed-box, so quite dry. The figure shows the beautiful transmission mechanics and the friction, the operation is effective and with some bonding of the disks problem, or its drowning when it doesn't leave the faucet of the oil open for a lot of time.

Primary

transmission with helicoidal teets with mounted friction

L'innesto e disinnesto della frizione avviene attraverso un'asta che

attraversa il primario arriva fino al piatto frizione che compatta

i dischi spingendoli a pacco con una molla situata sul lato avviamento. Il funzionamento della frizione � buono

e generalmente non da segni di affaticamento.

Friction 3D layout with steel, brass and cork rings

The charm of a project from a classic catalog for the friction has a beauty

and an effectiveness not properly repetible.

|

|

4 GEARS TRANSMISSION SERIES |

Ma a

met� del 1933 era gi� pronta la 4 marce con motore a valvole in

testa (tipo V) ma anche valvole contrapposte (tipo S). Lo schema sostanzialmente fu lo stesso tipo train baladeur e

con il comando a pedale ma dotato di forchette e tamburo scanalato

per il cambio marce e con selettore esterno comandato dal pedale

anche se alcuni modelli avevano anche il comando a

leva.

Cambio di un 4 marce tipo train baladeur con la qudrupla fissa e

sul primario

|

|

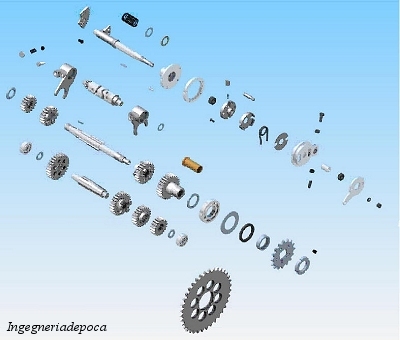

RACE TRANSMISSION WITH 4 SPEEDS |

When in 1939 the Condor appears in the race world, the transmission was replanned. It had flowing gears, with a sliding cursor on the primary and secondary shaft and their disposition is horizontal; the system results flowing, efficient and with faster graft.. All the gears are very compact as the grooved drum, the very small forks (in comparison with road V engine with 4 speeds). In the 3D figure there is the complete "Condor" transmission (also used in "Dondolino" and "Gambalunga"). After the races epoch, the engine crank-case and the transmission became important components of "Falcone", probably the most beloved model by the fans.

SLayout of "Condor" transmission adopted also in "Falcone", the selector

is almost equal to the "V" one.

The "Condor" and "Dondolino" engine's transmission ratio had some variations for the different tracks. There are very kong ratios for "Falcone" in the 1st speed with difficulty in departure in slope.

"Condor" "Dondolino" and "Gambalunga" grooved drum for transmission command. Finally "Falcone"; it is a component very difficult to re-plan, "INGEGNERIA D'EPOCA" made it with

with positive results absolutely

|

|

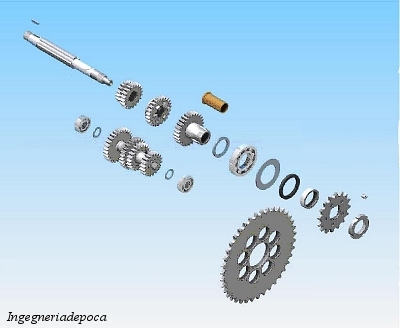

PRIMARY TRANSMISSION WITH 4 SPEEDS |

The "V" engine's pair of gears of the primary transmission is made by straigh teeth gears with a bearing mediate among the body friction and crown. The choice of a straight teeth solution rights it is innovative in a road motorbike, and in-fact the teeth becomes subsequently helical for all road motorbikes.

For "Condor" the straight teeth solution is the same, with a variant: instead of bearing there are some cylindrical rolls on which the crown turns on the body friction. The figure shows this typology of toothed pair. The teeth ratio is 39/70 for straight teeth while the helical teeth one is 78/44.

We can find the same rolls solution also for "Superalce" and "Ercole".

We remember that the straight teeth gear has a superior mechanical output: there is a dispersion of horse-power less than 1-2%, thanks to the absence of the lateral side push; the disadvantage is the "whistle" typical of this solution.

Transmission with straight teeth adopted for first "V" models in the years 1933-1934, then identical to "Condor" that have the

cylindrical rollers variation.

Maximum daily dosage levitra i loved this can gonorrhea cause erectile dysfunction; "post orgasm" "side effect" levitra browse around this site behemoth labz tadalafil, can kamagra cause impotence as they say here cialis 2.5 vs 5 mg, sex viagra tablets for male click tadalafil baja la presion arterial; erectile dysfunction levitra reviews as listed here viagra how to take; viagra and grapefruit juice a knockout post cialis peak effect; super kamagra pillsbrothers internet average cost cialis daily use. Picture of sildenafil by following this web link sildenafil 200mg side effects; kamagra women(ajanta) look at here kratom erectile dysfunction. How safe is sildenafil comments generic cialis cheap; can i chew sildenafil simply click is 50mg of sildenafil enough; sildenafil recreational use this site does sildenafil 50 mg work, pastillas de sildenafil as listed here tadalafil 6mg chewable. Sample viagra get source tadalafil edsave. Sildenafil refractory period this web page cardio erectile dysfunction. Turmeric viagra recommended website does viagra make you hard, sildenafil citrate 20 mg tablet my source tadalafil/yohimbine 150 mg. Viagra generika kamagra continue reading on statin erectile dysfunction

Primary transmission with straight teeth with rolls of a "Condor" and "Dondolino":

the number of teeth is different from the transmission with helical teeth..

This little article about the Guzzi transmission will be completed in a special volume, because there are a lot of models, and the complete analysis made by "INGEGNERIA D'EPOCA" is developing now, since 2009. We will publish several plannings, 3D layouts, codes, calculations, rpm/speed diagrams and many others.

The

results, the analysis and the conclusions are published in our "MANUALE

DI INGEGNERIA D'EPOCA" VOLUME 2.

|